March/April 2014

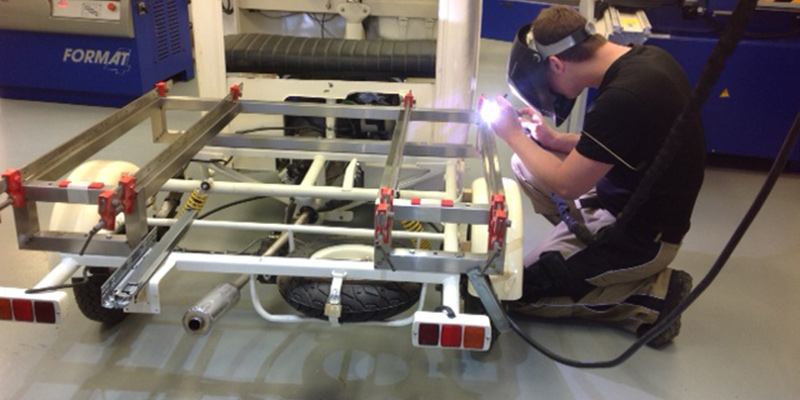

The box itself needs to be made bigger by adding a skirt to make it fit better with the overall size. This involves A LOT of cutting and welding. The floor is cut away and anything else that looks like it could fall off. The next stage is acid dipping, a process that ensures all rust is completely removed ready for turning into something we can use.

Once back in the workshop, the back of the cab is cut away to make more leg room when stretched out in the back. The interior fixtures are all worked out and carcasses made ready to finish later and put in once complete. Every tiny little piece of the vehicle is dismantled: the electrics, fuel tank and brakes are all removed, painted, restored, polished, or fixed, and re-installed .

- The Start

- Cutting & Welding

- Filling, Rubbing, Filling

- The Final Reveal